Measuring Length

Measuring Length – In everyday life we know a variety of sizes. One measure that we often encounter is length. Length has no limits and is often used to measure the length of the table, clothes and more.

With a clear measure, all needs can run smoothly and more easily. Long is one of the main areas of physics that has its own gauge. Units used in lengths include, millimeter, centimeter,and meter.

On this occasion YukSinau.co.id will discuss the complete length measurement tool in detail, from its understanding to its use. For more information, let us consider the following discussion.

Table of Contents

Measuring Length

Length measuring instrument is a tool or instrument used to calculate the length of an object, units in length commonly used are meters and centimeters. Examples of length measuring instruments that are often used are the bar and the meter.

Types of Length Measurements

In everyday life there are long gauges used, some of them are meter, calipers,screw miktomter,crossbar and many more.

The following is an explanation of several types of length measuring instruments that are often used in everyday life.

Micrometer Screw

Micrometer screw is a length measuring instrument used to measure the outside diameter of an object. The screws meter has a level of accuracy up to 0,01 millimeters or far higher than the calipers.

The micrometer screw has several parts, The following are the parts of the micrometer screw and their use.

- Frame (Frame)

The framed or often called section of the micrometer frame is a section with a shape such as the letter C or the U letter made of heat-resistant metal., thick and strong.It aims to minimize the occurrence of foam foam that can interfere with the measurement process on an object.

- Fixed Shaft (Anvil)

The next part is the fixed axis or also known as anvil. This section serves to hold the object when the object will be cured with a screw micrometer. - Axle of Motion (spindle)

The next part of the micrometer screw is the axis of motion, also known as spindle. The shaft is a cylinder that can be moved to the micrometer fixed axis. - Locking (Lock Nut)

The fourth part of the Micrometer Screw is Locking (lock) which serves to hold the Motion Shaft so as not to move when the measurement process on an object. - Main Scale (Sleeve)

The fifth micrometer on the screw is the main scale, also called Sleeve which is the location of the Main Scale with Millimeter units (mm). - Scale Play (Thimbel)

The sixth part of the screw micrometer is the rotary scale. A rotary scale is a rotary scale that functions as a nonius micrometer scale. - Ratchet Knob

Ratchet knob is part of the micrometer screw that is used to function to rotate the shaft of motion when the end of the shaft of motion is approaching the object to be measured, and is used to tighten the shaft of motion until you hear a sound.This serves to ensure that the Edge of the Motion Axle has been perfectly attached to the object to be measured then the Ratchet Knob must be rotated as much as two to three turns.

Ruler

Ruler is a length measuring instrument that is often used in everyday life. In general, a ruler is made of wood , plastic and iron. The ruler has the main function as a length measuring instrument and drawing straight lines.

When making measurements using a ruler, then the direction of our vision must be perpendicular to the scale on the ruler and the object being measured. If the view is not perpendicular it will cause an error in the measurement, can be smaller or larger than the original size.

Ruler also has many types such as triangle ruler , elbow ruler , pattern ruler (usually used in the process of sewing). The price of this ruler varies depending on the size and quality of the material used.

This gauge has the smallest scale 1 mm or 0,1 cm. The ruler has a measurement accuracy of half of its smallest scale, i.e. 0,05 cm.

Meter

The meter is a length measuring instrument made with flexible material that can be rolled up and is easy to carry anywhere. The meter is generally used as a tool to measure large objects in carpentry and also as a tool to measure soil, street width and building.

The most commonly used metal in carpentry is called roll meter made using thin iron plate material which is generally long 3 – 10 meter. Meanwhile, the type of meter used to measure land and buildings is known as fiber meter or roll meter made from plastic tape which generally has a length of up to 50 meter.

The meter has an accuracy of up to 0.5mm. Generally the meter uses a unit of mm to cross the cm and measure the unit of feet or inches.

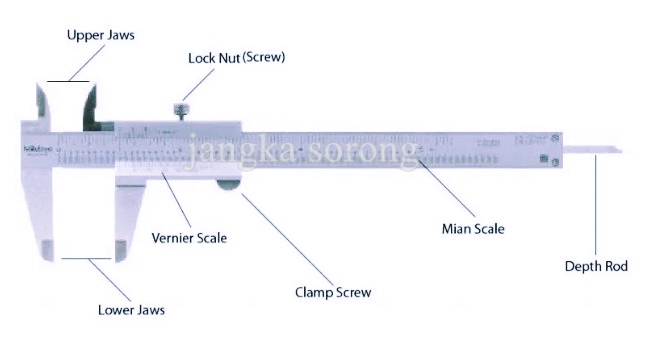

Calipers

Caliper is a length measuring instrument commonly used to measure the diameter of an object. The wheelbarrow was discovered by a technician named Pierre Vernier. The calipers are also called Vernie Capiler.

Along with the times, the term shoves develops on the board of digital boards. It aims to facilitate the diameter both inside and outside diameter and thickness of an object. The numbers that appear will be digital rather than manual.

The following are the parts of the calipers.

- Outer Jaw, serves to measure the outside of objects.

- Deep jaw, function to measure the inside of objects.

- Depth checker, function to measure hole depth.

- Main scale (centimeter)

- Main scale (inch)

- Skala nonius (centimeter)

- Skala nonius (inch)

- Holder, function to withstand shifts.

The length scale on the jaw remains the main scale, while the short scale on the sliding jaw is a nonius or vernier scale. The main scale has scales in cm and mm. And the nonius scale has a length 9 mm and divided by 10 scale.

So the difference between one nonius scale and one scale on the main scale is 0,1 mm or 0,01 cm. So, it can be concluded that the smallest scale on calipers is 0,1 mm or 0,01 cm. And uncertainty in calipers is 0,005 cm or 0.05mm.

The advantage that is owned by Sorong Jahka is that in addition to making it easier to measure, the results are more accurate. Besides being used in the field of building construction, calipers are often used in the field of mechanical engineering and workshop.

Height Gauge

Height gauge is a length measuring instrument used to measure the height of an object against a plane of reference and can also be used to provide marks by scratching the workpiece of the machining process. The first type is often used in surgery doctors to measure a person's height.

Height gauge has two columns rotating. This gauge is used in metrological or metal work to measure upright distances. To improve accuracy in measurement is to reduce deflection of the workpiece, Height gauge is often paired to the dual probe dial indicator.

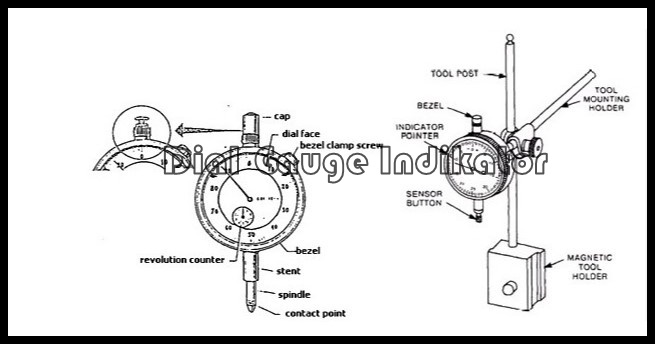

Dial Gauge Indicator

Components of Dial Gauge Indicator is a measuring needle and is equipped with a device that can support for example a block of a magnetic base, tongs and supports. Dial Gauge Indicator has two scales namely a large scale consisting of 100 Small strips and scales. On a large scale each strip has a value 0,01 mm.

When the long needle rotates 1 full times it shows that the measurement results are 1mm and the small scale is the counter rotation of the long needle on a large scale.

Like for example, when a long needle in a large scale moves far 7 the strip while the needle on a small scale moves at the scale 3 then the results of these measurements are 3,07 mm. The results of these measurements can be obtained from :

* The scale on the long needle is read : 7 x 0,01 mm = 0,07 mm

* The scale on the short needle is read : 3 x 1 mm = 3 mm

* Then the measurement results are 0,07 mm + 3 mm = 3,07 mm.

Thus our explanation of the "Length Measuring Instrument."” hopefully can be useful as physics learning materials. To find out other physics material visit the article below.

Other Articles :

- Gauss's Law

- Lenz's Law

- Electromagnetic wave

- Black Body Radiation

- Potential Energy Formula

- Unidirectional Electric Current

- Solid substance

- Gas Laws

The post Long Measurement Tool appeared first on YukSinau.co.id.